Predictive Analytics

Predict-It

Predict-It monitors critical equipment in real-time process environments and uses advanced predictive computational methods to recognize potential future outages

Unleashing Predictive Analytics: Unlocking Future Insights

Enhance Equipment Reliability with Real-Time Predictive Monitoring by Predict-It

Read more about Pathway?

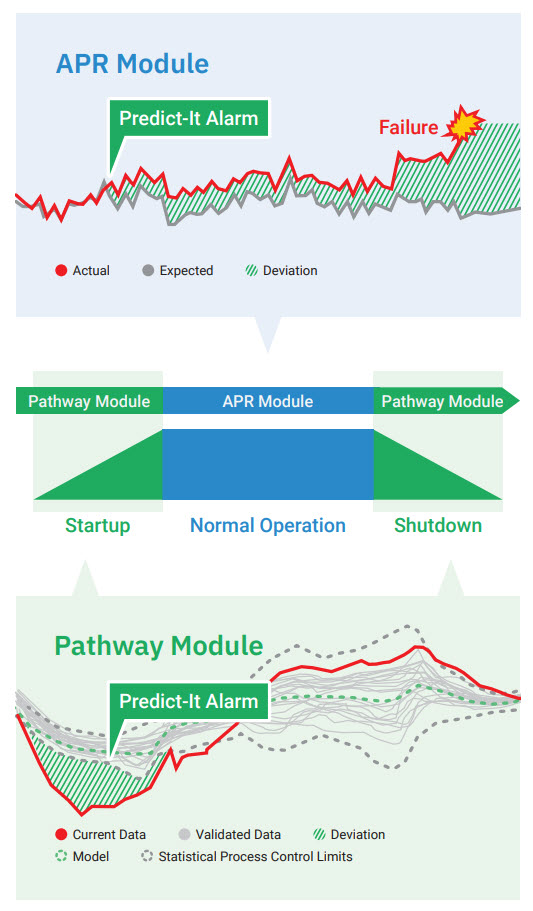

The Pathway module expands upon the functionality of Predict-It by adding equipment-monitoring capabilities for startups, shutdowns, and other transient-state processes with a defined start and end. Protect your assets during vulnerable phases of operation, when changing conditions demand peak performance.

See how AGL reaped the benefits of ECG's Predictive Analytics platform, Predict-It

Predict Issues Before They Become Problems

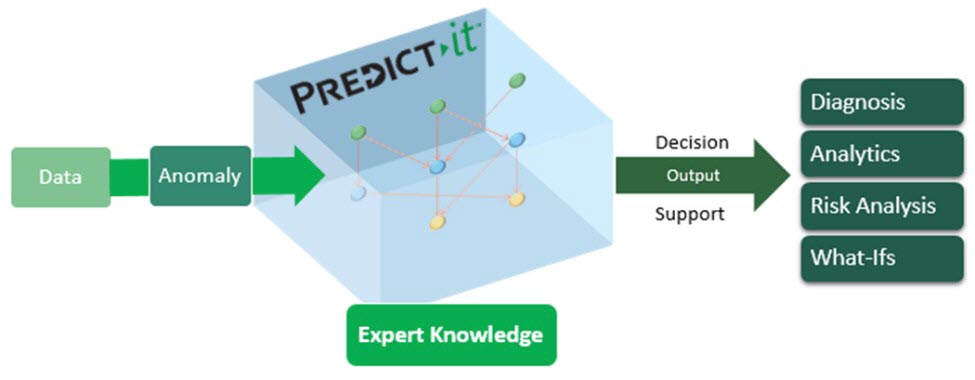

Predict-It is a powerful analytical solution for Aveva PI System users that monitors the health of critical process equipment. Predict-It’s anomaly detection modules cover all modes of operation, from start-up, through normal load, and shut-down. Highly accurate anomaly detection and correction of equipment degradation earlier in the development of faults help to keep your assets operating at higher availability, reducing ancillary damage, minimizing cost to repair while avoiding failures and lost revenue.

Advanced Pattern Recognition Module

Unlike products that monitor equipment using a first-principles approach, Predict-It employs Advanced Pattern Recognition for early detection of significant events. Modeling algorithms track trends in process variables on a continuous basis and compare them to historical operation. This Digital Twin Technology acts as a virtual model of an asset, creating a predicted trend that runs simultaneously with real-time equipment data.

Pathway Module

Quickly changing conditions can cause deterioration of mechanical assets, which will require additional a different type of monitoring. Predict-It’s Batch Module uses Multivariant Data Analysis. MVDA provides a summary of key variable influences, allowing faster interpretation and interrogation of start-up, shut-downs, or batch processes. Flagging batches, start-ups and shut-down that exceed statistical limits shines a light on developing issues that may not be seen during normal operation.

Diagnose Faults with Expertise

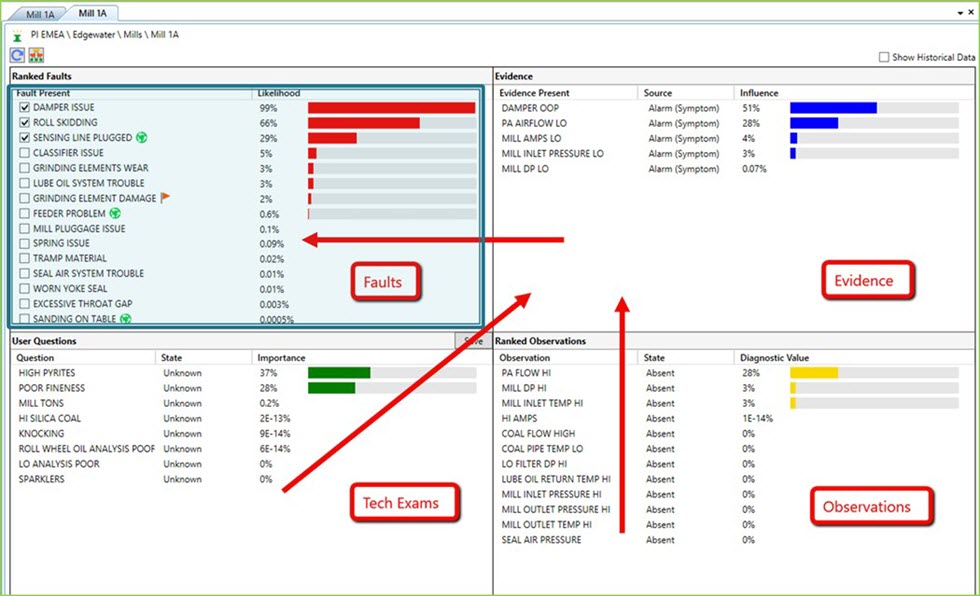

Once Predict-It detects an asset anomaly, engineers are tasked with putting a plan in place for addressing that situation. From compiling information on the anomaly behavior to diagnosing a potential fault, Predict-It has streamlined this process with the Diagnostic Reasoner Module. The Diagnostic Reasoner unites the knowledge of the Subject Matter Experts with a database of equipment specific faults in a Bayesian framework, allowing differentiation and bringing clarity in scenarios that involve uncertainty as an equipment issue evolves.

Diagnostic Reason Module

High Level Use Case

- Real Time Diagnosis

- Play out “What-If” Scenarios to support decision-making

- Differential Diagnosis helps to pinpoint equipment faults

Benefits

- Shorten troubleshooting time

- Tailored Diagnostics for each asset manufacturer and mode

- Ability to assess multiple faults simultaneously

- ECG Fault Library provides quick time to value

Learn more on how automating asset diagnosis can add value to your maintenance practices

Product Video

Product Support

Access guides, manuals, software downloads, training videos, and more in our product support center.